Polyethylene Packaging: The Ultimate Solution for Product Protection

In today’s highly competitive marketplace, ensuring your products arrive safely while presenting a professional image has become a critical part of any successful business strategy. One of the key innovations supporting this goal is polyethylene packaging, a versatile and reliable material that safeguards goods during transit and storage. Whether you require packaging for fragile electronics or custom foam inserts for delicate artifacts, polyethylene-based solutions offer unmatched protection and customization options.

This article explores the benefits, applications, and evolving innovations in polyethylene packaging, focusing on polyethylene foam inserts and their role in modern protective packaging.

What is Polyethylene Packaging?

Polyethylene packaging refers to protective materials made from polyethylene polymer, commonly used in foam form for cushioning and insulation. Unlike traditional materials such as polystyrene, polyethylene foam is a cross-linked foam known for its durability and resilience. It absorbs shocks efficiently, making it ideal for products that endure repeated handling, transport knocks, and long-term storage.

The structure of polyethylene foam comprises tiny closed cells acting as shock absorbers, providing reliable multi-drop protection that does not degrade over time. This characteristic ensures that your products remain safe through multiple shipping cycles, unlike less durable foams that break down quickly.

Benefits of Polyethylene Foam Inserts in Packaging

1. Superior Protection Against Impact

One of the most significant advantages of polyethylene foam inserts is their ability to absorb and distribute impact forces. This feature is vital for protecting fragile and high-value items like electronics, medical devices, or fine art. The foam’s cellular structure cushions the product by minimizing vibration and sudden shocks, reducing the risk of damage substantially.

2. Resistance to Moisture, Chemicals, and Temperature Changes

Polyethylene foam is inherently resistant to moisture and many chemicals, which adds an extra layer of protection for sensitive products. This moisture barrier helps prevent corrosion or degradation of the packaged items, especially for electronics and precision instruments vulnerable to humidity. Its thermal stability also makes it suitable for environments with fluctuating temperatures.

3. Versatility and Customization

Polyethylene foam packaging is available in various colors, including black, white, blue, and anti-static pink. Many products are branded under trade names like Ethafoam, Stratocell, or Jiffycell Polylam, which are used by packaging specialists worldwide.

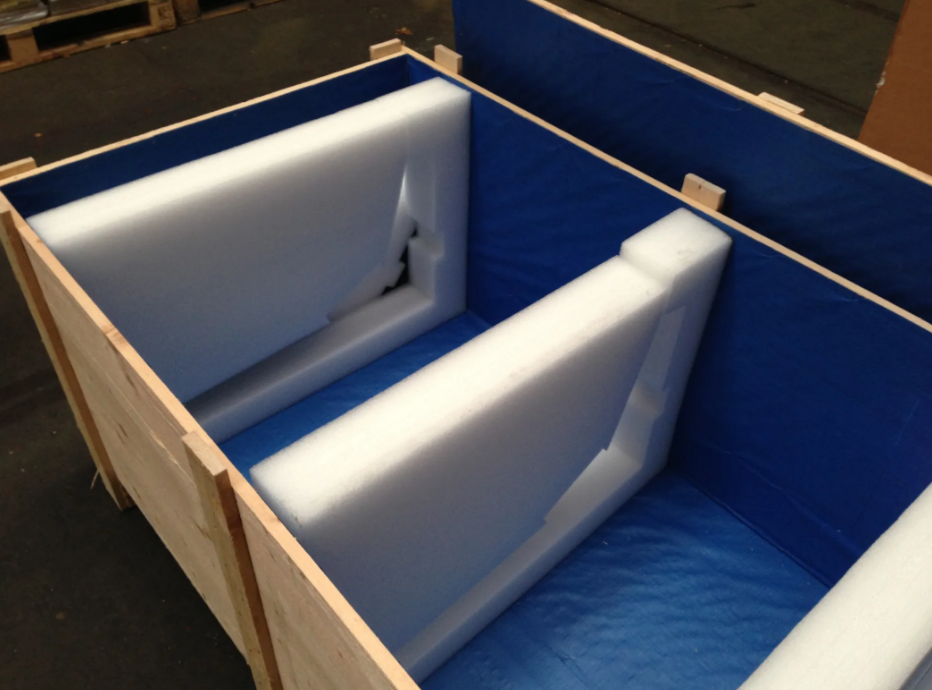

Moreover, polyethylene foam can be custom-cut and shaped into foam inserts tailored precisely to the shape and size of your product. This bespoke fit prevents movement inside the packaging, adding an extra level of security.

4. Reusability and Sustainability

While polyethylene foam is more expensive than some alternatives like polystyrene, its reusability makes it cost-effective over time. Many businesses choose polyethylene packaging for products that require multiple shipments or long-term storage, as the material retains its cushioning properties.

Additionally, many manufacturers now offer eco-friendly polyethylene options and complement them with sustainable outer packaging materials. This combination helps companies reduce their environmental impact and appeal to the growing number of eco-conscious consumers.

See also: Buying an Internet Business: What You Need to Know

Polyethylene Packaging Solutions for Diverse Industries

Electronics and Technology

The electronics sector demands packaging solutions that protect delicate circuits and components from shocks, moisture, and static electricity. Polyethylene foam inserts are frequently used to safeguard smartphones, computers, and other devices, ensuring safe delivery and handling.

Medical and Healthcare Products

Medical equipment and sensitive instruments require hygienic and protective packaging. The chemical resistance and cushioning ability of polyethylene foam make it perfect for shipping and storing healthcare devices, pharmaceutical products, and diagnostic tools.

Automotive and Industrial Equipment

For industrial parts and automotive components, polyethylene packaging offers the strength and durability necessary to withstand harsh transit conditions. Custom foam inserts can securely hold tools and parts in place during shipping, reducing damage and returns.

Art, Collectibles, and Archival Storage

Museums, galleries, and collectors trust polyethylene foam packaging for archival storage and shipping of delicate artefacts and artworks. Bespoke foam inserts prevent movement and physical damage, preserving the value and integrity of historical items.

The Complete Packaging Service: From Cartons to Foam Inserts

A major advantage of sourcing polyethylene packaging from specialized providers is the complete packaging solution they offer. Companies like Advanced Protective Packaging not only supply the foam inserts but also match these with outer cartons and boxes, simplifying logistics and ensuring compatibility.

This holistic approach minimizes stock imbalances, reduces procurement times, and offers a single point of contact for customer support. Additional products such as bubble wrap, tape, and other packing materials are often available from the same supplier, creating an all-in-one packaging package.

Bespoke Polyethylene Foam Inserts

Beyond protection, custom-designed polyethylene foam inserts elevate the unboxing experience. Precision-cut foam can be crafted in various colors and shapes, tailored to cradle the product perfectly. This creates a premium presentation, showing customers that the brand values quality and attention to detail.

Such bespoke inserts are popular in industries where presentation matters — luxury goods, corporate gifts, and collectible items benefit from packaging that both protects and impresses.

Eco-Friendly Innovations in Polyethylene Packaging

Sustainability is now a top priority for many companies and consumers alike. Recognizing this trend, polyethylene packaging manufacturers are increasingly using recycled and recyclable materials in their foam products.

Custom packaging designs can also incorporate biodegradable outer packaging, water-based inks, and reduced material waste through precise foam cutting techniques. These eco-conscious solutions not only lessen environmental impact but also enhance brand reputation by aligning with consumer values.

Conclusion

Polyethylene packaging, especially when paired with custom polyethylene foam inserts, represents a powerful combination of protection, versatility, and sustainability. From fragile electronics to priceless collectibles, this packaging solution offers:

- Reliable multi-drop shock absorption

- Moisture and chemical resistance

- Reusable and durable materials

- Complete packaging services for simplified sourcing

- Customization for both protection and aesthetics

- Environmentally responsible options to meet today’s sustainability goals

Choosing polyethylene packaging means investing in the safety and presentation of your products, helping you build trust with customers and stand out in a crowded marketplace.

Need Tailored Packaging Solutions?

If you want to enhance your product protection with bespoke polyethylene foam inserts or require a full packaging service from design to delivery, speaking to an expert packaging provider is your next step. Request a free quotation today and discover how polyethylene packaging can safeguard your products and boost your brand’s impact.